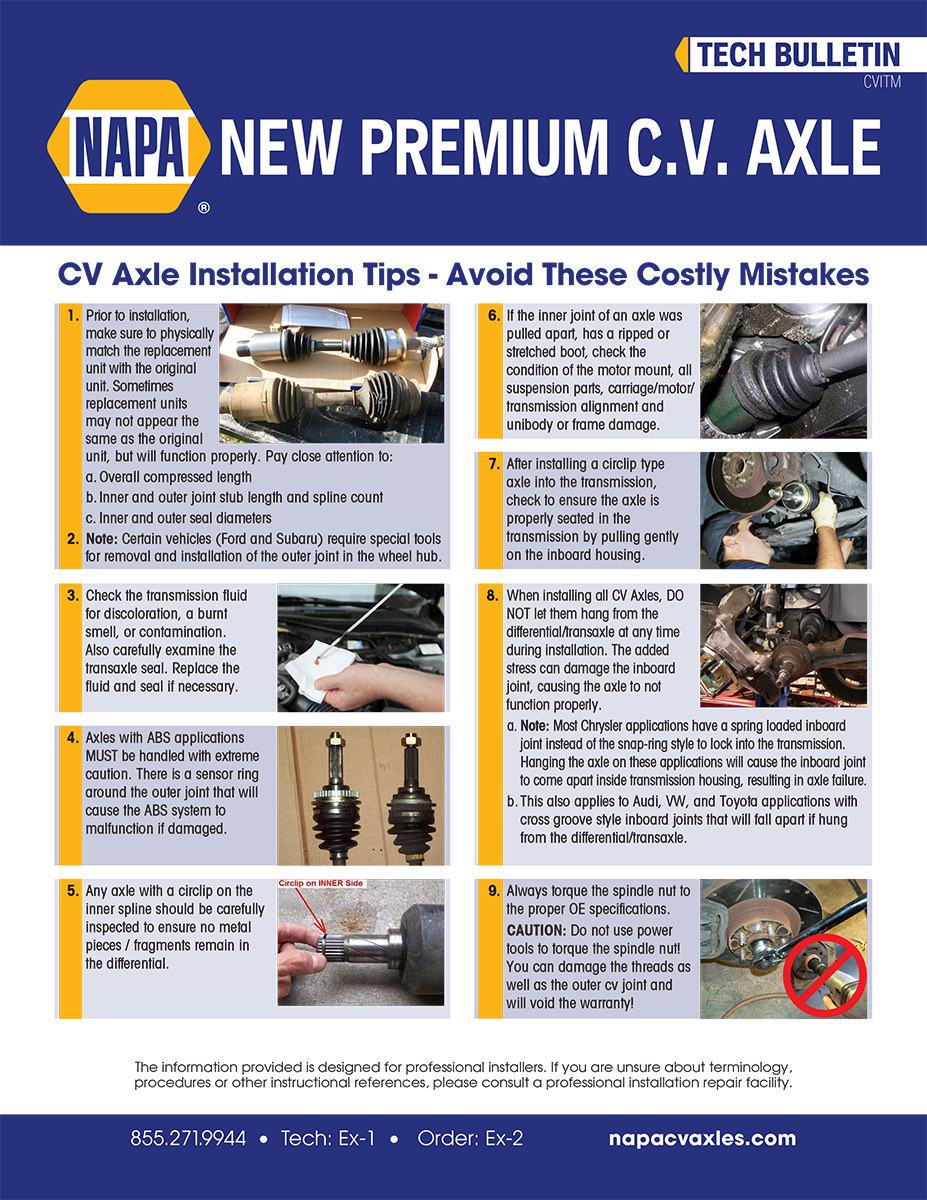

CV Axle Installation Tips – Avoid These Costly Mistakes

ONE

Prior to installation, make sure to physically match the replacement unit with the original unit. Sometimes replacement units may not appear the same as the original unit, but will function properly. Pay close attention to:

- Overall compressed length

- Inner and outer joint stub length and spline count

- Inner and outer seal diameters

TWO

Note: Certain vehicles (Ford and Subaru) require special tools for removal and installation of the outer joint in the wheel hub.

THREE

Check the transmission fluid for discoloration, a burnt smell, or contamination. Also carefully examine the transaxle seal. Replace the fluid and seal if necessary.

FOUR

Axles with ABS applications MUST be handled with extreme caution. There is a sensor ring around the outer joint that will cause the ABS system to malfunction if damaged.

FIVE

Any axle with a circlip on the inner spline should be carefully inspected to ensure no metal pieces / fragments remain in the differential.

SIX

If the inner joint of an axle was pulled apart, has a ripped or stretched boot, check the condition of the motor mount, all suspension parts, carriage/motor/transmission alignment and unibody or frame damage.

SEVEN

After installing a circlip type axle into the transmission, check to ensure the axle is properly seated in the transmission by pulling gently on the inboard housing.

EIGHT

When installing all CV Axles, DO NOT let them hang from the differential/transaxle at any time during installation. The added stress can damage the inboard joint, causing the axle to not function properly.

a. Note: Most Chrysler applications have a spring loaded inboard joint instead of the snap-ring style to lock into the transmission. Hanging the axle on these applications will cause the inboard joint to come apart inside transmission housing, resulting in axle failure.

b. This also applies to Audi, VW, and Toyota applications with cross groove style inboard joints that will fall apart if hung from the differential/transaxle.

NINE

Always torque the spindle nut to the proper OE specifications.

CAUTION: Do not use power tools to torque the spindle nut! You can damage the threads as well as the outer cv joint and will void the warranty!