Addressing Three Common CV Axle Issues

1. Removal & Installation Issues

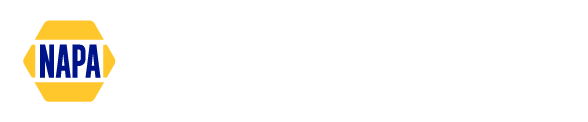

REMOVAL

Problem: Prying and striking the axle during removal often causes the circlip to become caught and damages both the axle and transmission splines.

Solution: Use a CV removal tool that attaches to a slide hammer is the best method of removal to avoid damage to the splines.

INSTALLATION

Problem: The most common cause of warranty returns is improper installation. Circlips are often damaged during installation due to not being properly centered.

Solution: A small amount of grease applied to the circlip will keep it centered and prevent damage during installation.

2. Addressing Subaru Vibration Issues

Problem: Subaru transmission mounts are susceptible to becoming very spongy and wear out due to the unique horizontal movement of a boxer (cylinders horizontally opposed) engine. When these mounts wear, they cause the engine/transmission to sit slightly off center.

Solution: Inspect and replace the transmission mount (if worn) to eliminate off center vibration issues. Note: If the mount is worn, the articulation angle of the new replacement axle becomes the mount that is holding the transmission in the correct location, which creates a binding vibration.

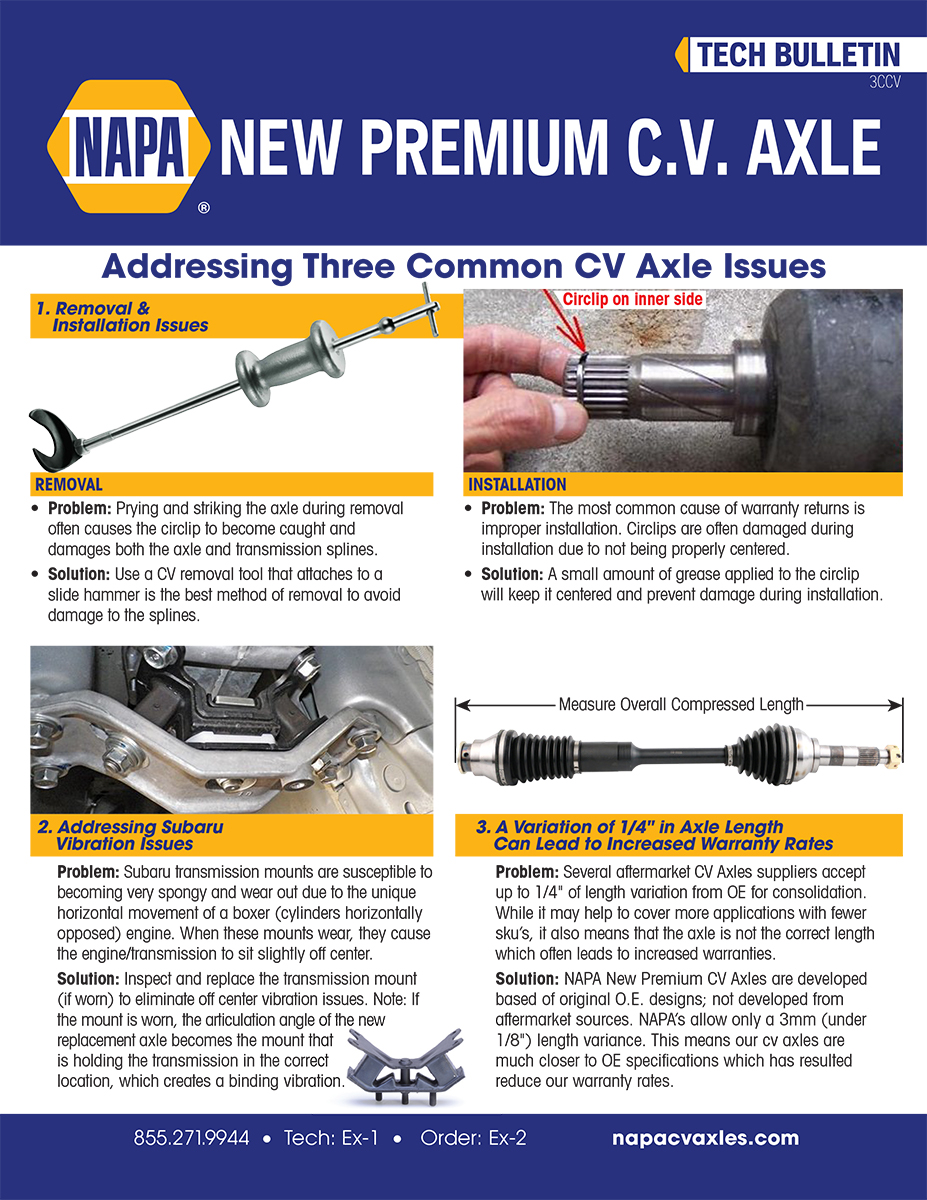

3. A Variation of 1/4″ in Axle Length Can Lead to Increased Warranty Rates

Problem: Several aftermarket CV Axles suppliers accept up to 1/4″ of length variation from OE for consolidation. While it may help to cover more applications with fewer sku’s, it also means that the axle is not the correct length which often leads to increased warranties.

Solution: NAPA New Premium CV Axles are developed based of original O.E. designs; not developed from aftermarket sources. NAPA’s allow only a 3mm (under 1/8″) length variance. This means our cv axles are much closer to OE specifications which has resulted reduce our warranty rates.